We focus on providing high-performance engineering solutions that are perfectly aligned with our customers’ expectations.

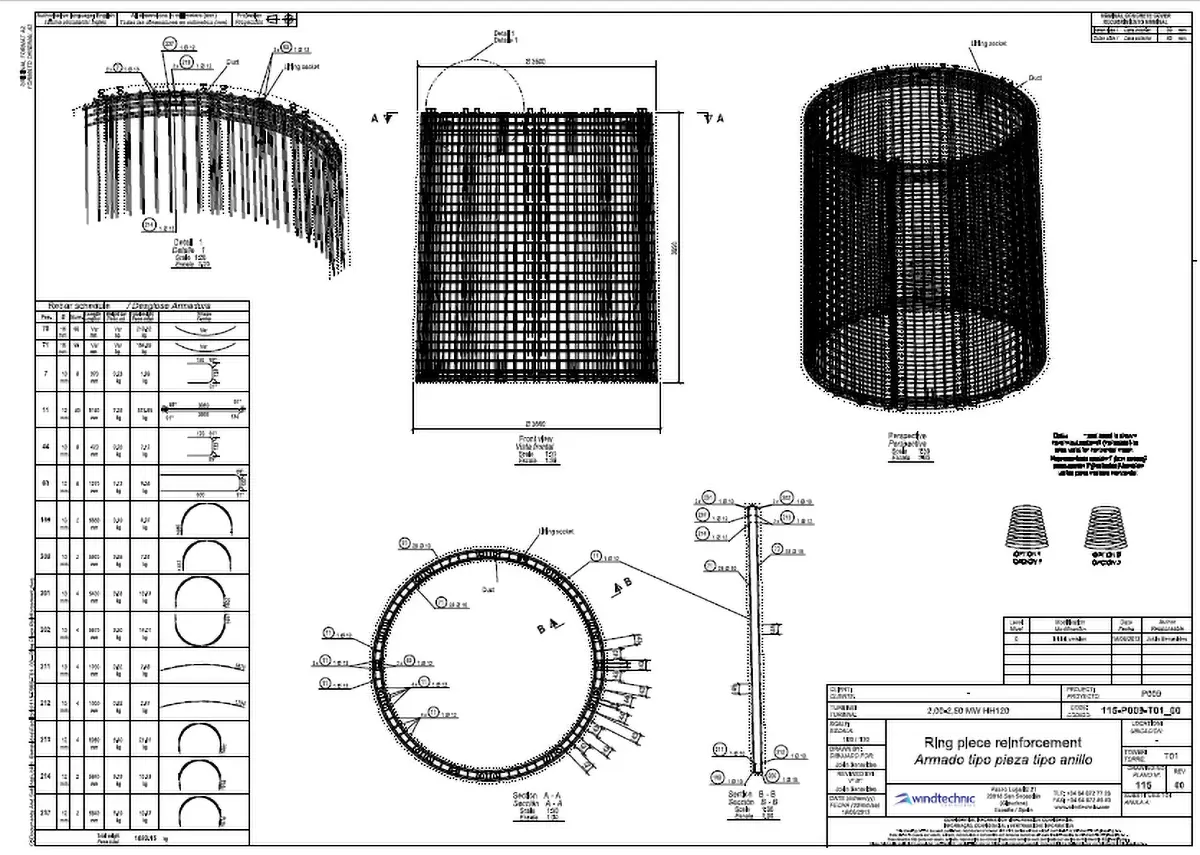

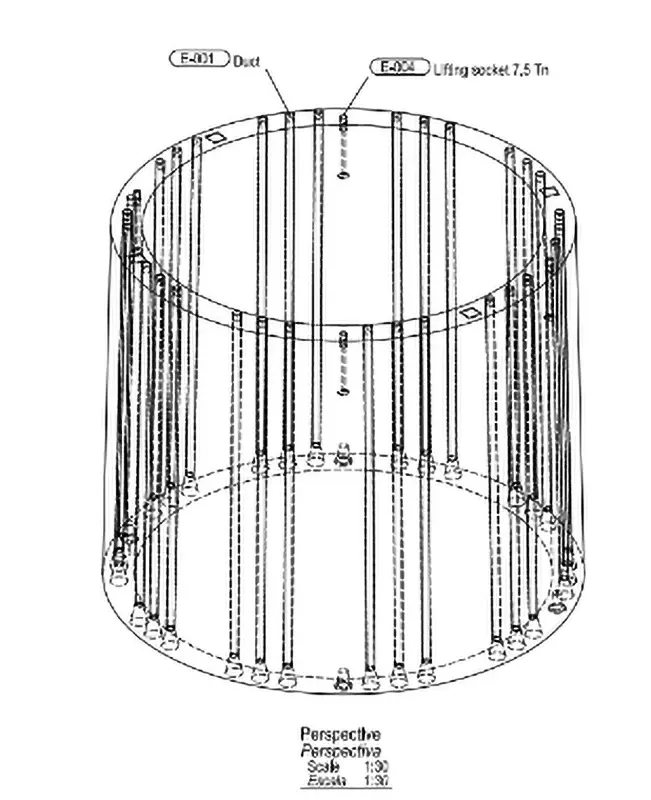

Our range of services includes the structural design and certification of concrete wind towers, as well as the detailed development of their internal components, molds, tooling, and definition of manufacturing and assembly processes.

WINDTECHNIC specializes in designing customized tower and foundation solutions that precisely fit the demand and needs of the client, market, and project. This capability stems from our diverse expertise, which includes among others: the design of reinforced and prestressed concrete and steel structures, our good understanding of wind turbine loads and structural dynamic behaviour, our experience in complying with international and local regulations, as well as our know-how of guidelines and requirements for certification.

Windtechnic has performed over 100 tower designs for turbines ranging from 2 MW to 7 MW rated power and 90 m to 165 m hub heights.

Certification of the designed structures is essential to guarantee exceptional quality and full compliance with international regulations (like IEC, DIBT, EN, etc.). Over time, we have collaborated in the approval of our innovative designs with various globally renowned certification bodies, such as Germanischer Lloyd (GL), Det Norske Veritas (DNV), and TÜV Nord.

With solid and proven experience, WINDTECHNIC provides solutions for the design, manufacturing, and installation of internal components of wind towers. All our work is carried out in strict accordance with the most prestigious international standards and regulations, such as IEC, EN, OSHA, etc.

WINDTECHNIC offers design and manufacturing of the molds required to cast the concrete tower segments. In addition, we guarantee the quality of the designed molds, advising and controlling the manufacturing processes on site.

WINDTECHNIC is responsible for defining and designing all the required manufacturing and assembly processes to guarantee the success of the projects.

Our scope includes among others: design of precast facilities (mobile, permanent, on land or in port), definition of production processes including the necessary equipment and resources, preparation of manuals, specifications, and quality control documentation, and study of assembly strategies adapted to the resources and crane availability.

With a solid track record and international experience, WINDTECHNIC offers tailored analysis for both onshore and offshore wind energy sector.

Our services include among others: technical feasibility studies, cost comparisons between different alternatives, analysis of local regulations, detailed evaluation of critical elements (e.g. through finite element models), implementation of monitoring systems, design of tests and interpretation of results, etc.

Our team of experts in engineering and construction of concrete towers is always ready to offer customized and sustainable solutions adapted to your needs.